-

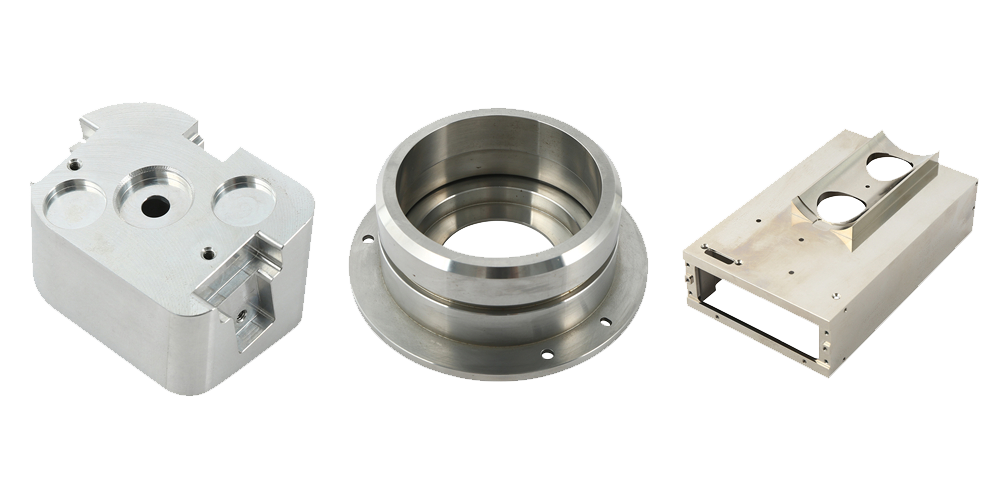

Customized CNC Machining Copper

Customized CNC Machining CopperProduct category: CNC Machining Copper

Processing Technic:CNC machining,CNC milling,CNC turning,EDM,Punching,Drilling, Broaching ect.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:Prototype is acceptable.

QC system:100% inspection before shipment

Packing:Poly bag,Carton,as per customer's requirement

Precision CNC Machining Copper

Precision CNC Machining CopperProduct category: CNC Machining Copper

Processing Technic:CNC machining,CNC milling,CNC turning,EDM,Punching,Drilling, Broaching ect.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:Prototype is acceptable.

QC system:100% inspection before shipment

Packing:Poly bag,Carton,as per customer's requirement

CNC Machining Copper service

CNC Machining Copper serviceProduct category: CNC Machining Copper

Processing Technic:CNC machining,CNC milling,CNC turning,EDM,Punching,Drilling, Broaching ect.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:Prototype is acceptable.

QC system:100% inspection before shipment

Packing:Poly bag,Carton,as per customer's requirement

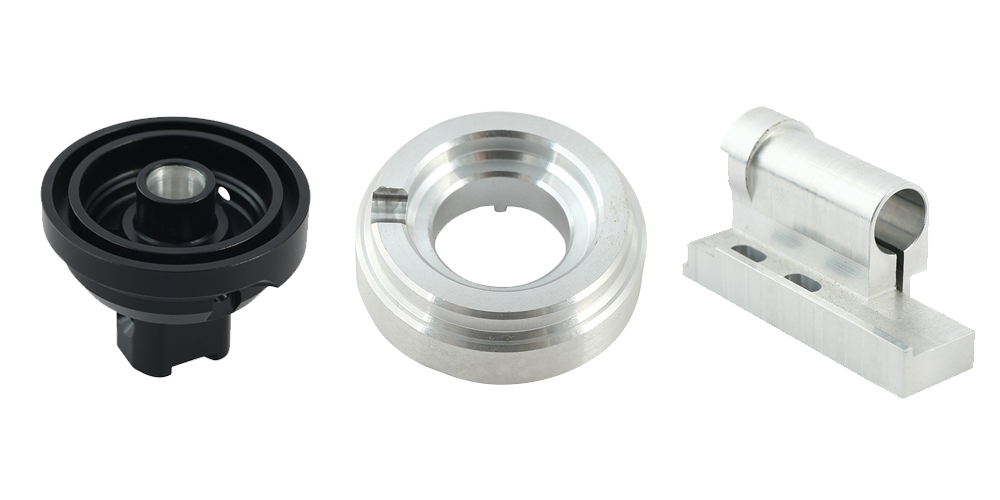

CNC Machining Copper solution

CNC Machining Copper solutionProduct category: CNC Machining Copper

Processing Technic:CNC machining,CNC milling,CNC turning,EDM,Punching,Drilling, Broaching ect.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:Prototype is acceptable.

QC system:100% inspection before shipment

Packing:Poly bag,Carton,as per customer's requirement

CNC Machining Copper supplier

CNC Machining Copper supplierProduct category: CNC Machining Copper

Processing Technic:CNC machining,CNC milling,CNC turning,EDM,Punching,Drilling, Broaching ect.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:Prototype is acceptable.

QC system:100% inspection before shipment

Packing:Poly bag,Carton,as per customer's requirement

CNC Machining Copper OEM

CNC Machining Copper OEMProduct category: CNC Machining Copper

Processing Technic:CNC machining,CNC milling,CNC turning,EDM,Punching,Drilling, Broaching ect.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:Prototype is acceptable.

QC system:100% inspection before shipment

Packing:Poly bag,Carton,as per customer's requirement

China CNC Machining Copper

What is CNC Machining Copper service

CNC Machining Copper's CNC lathe feed processing path refers to the path that the turning tool moves from the tool setting point (or the fixed origin of the machine tool) to the point and ends the processing program, including the cutting path and the non-cutting path of the tool cutting in and out.

The feed route of finishing is basically carried out along the part contour sequence. Therefore, the focus of determining the feed path is to determine the feed path for rough machining and idle stroke. In the CNC machining of CNC Machining Copper, the determination of the machining route generally follows the following principles.

① It should be able to guarantee the accuracy and surface roughness of the workpiece to be processed.

② Make the processing route the shortest, reduce idle travel time, and improve processing efficiency.

③Simplify the workload of numerical calculation as much as possible and simplify the processing procedure.

④ For some reusable programs, subroutines should be used.

What is CNC Machining Copper service: What is CNC Machining Copper?

Traditional CNC Machining Copper machining is done by manual operation of ordinary machine tools. During the processing, the machine tool is hand shaken to cut the metal, and the accuracy of the product is measured with the naked eye with tools such as calipers. Modern industry has already used computer numerically controlled machine tools for operation. The CNC machine tool can automatically process any products and parts directly according to the program written by the technicians in advance. This is what we call "CNC machining".

CNC machining is widely used in any field of CNC Machining Copper machining. It is the development trend and important and necessary technical means of mold processing. CNC Machining Copper is a method that uses digital information to control the movement and processing of machine tools. Machine tools that use numerical control technology to achieve processing control, or machine tools equipped with numerical control systems, are called numerical control machine tools. The numerical control system includes: numerical control device, programmable controller, spindle drive and feed device. CNC machine tools are highly integrated products of machine, electricity, liquid, gas and light. To realize the control of the machine tool, it is necessary to use geometric information to describe the relative movement of the tool and the workpiece, and use process information to describe some process parameters that the machine tool must have.

For example: CNC Machining Copper's feed rate, spindle speed, spindle forward and reverse rotation, tool change, coolant switch, etc. The information of these CNC Machining Copper forms a processing file (that is, a normal CNC processing program) in a certain format and is stored on an information carrier (such as a disk, punched tape, tape, etc.), and then read in by the CNC system on the machine tool (or directly Input through the numerical control system keyboard, or input through communication), through its decoding, make the machine tool move and process parts. Modern CNC machine tools are typical products of mechatronics, and are the technical basis for a new generation of production technology and computer integrated manufacturing systems. The development trend of modern CNC machine tools is high-speed, high-precision, high-reliability, multi-function, composite, intelligent, and open structure.

The main development trend of CNC Machining Copper is to develop an intelligent full-function general-purpose CNC device with an open structure of software and hardware. Numerical control technology is the foundation of processing automation and the core technology of CNC machine tools. The level of CNC Machining Copper is related to the country's strategic position and the level that reflects the country's comprehensive strength. CNC Machining Copper keeps up with the development of information technology, microelectronics technology, automation technology and testing technology. developing.

CNC Machining Copper is a CNC machine tool with a tool magazine, which can automatically change the tool and perform various machining operations on the workpiece within a certain range. The characteristic of CNC Machining Copper machining center is: After the machining part is clamped once, the CNC system can control the machine tool to automatically select and replace the tools according to different procedures; automatically change the spindle speed, feed speed and the auxiliary functions of the tool relative to the workpiece. , Continuously and automatically carry out drilling, countersinking, reaming, boring, tapping, milling and other multi-process workpieces for each processing surface. Because CNC Machining Copper's machining center can centrally and automatically complete a variety of processes, it avoids human error, reduces workpiece clamping, measurement and machine tool adjustment time, workpiece turnover, handling and storage time, and greatly improves processing efficiency and processing accuracy. Therefore, it has good economic benefits. Machining centers can be divided into vertical machining centers and horizontal machining centers according to the position of the spindle in the space.

Boyang is a leading China CNC Machining Copper factory that focuses on CNC Machining Copper. We focus on producing high-quality Boyang CNC Machining Copper with complete specifications.

Boyang CNC Machining Copper

When designing and developing new products according to customer needs, we strictly control quality standards while controlling production costs.