China CNC Machining Steel

CNC Machining Steel:

CNC machining center, quenching 60 degree steel, what should be the roughing speed, what is the feed rate, for hardened steel parts above 60 degrees, the CBN tool has high processing efficiency and is suitable for continuous processing conditions. For example, in the case of continuous finishing of hardened steel gears, use is appropriate. If it is intermittent processing, it is suitable for use, and it has both collapse resistance and abrasion resistance.

Features of CNC Machining Steel:

Stainless steel itself is not hard, but it has strong toughness, poor cutting performance, and easy to stick, so it hurts the knife, the workpiece is easy to change, and it is easy to work hardening. The cutting tool should be sharp, the speed should not be high, and the cutting fluid concentration should be high.

CNC Machining Steel: How does CNC machine stainless steel tungsten steel tools above 60 degrees, 10 diameter tools, local roughness, speed, cutting 0, 2~0, 25, feed.

Several key points to improve the quality of CNC Machining Steel:

1. Reasonable use of CNC machining tools

Processing steel and copper tools must be strictly distinguished, and the margin of the light knife must be reasonable, so that the smoothness of the workpiece and the service life of the tool will be better.

2. Before CNC Machining Steel machining, use a calibrator to check whether the tool swing is within the allowable tolerance range. The cutter head and lock nozzle should be blown clean with an air gun or wiped with a cloth before processing. You can install a knife. Too dirty has a certain impact on the accuracy and quality of the workpiece.

3. When clamping, pay attention to whether the name and model of the workpiece processed by CNC Machining Steel are consistent with the program table, whether the material size matches, whether the clamping height is high enough, and the number of calipers used.

4. The CNC Machining Steel program table should be consistent with the reference angle direction marked by the mold, and then check whether the 3D drawing is correct, especially the workpiece that has been drilled and transported. Be sure to see if the 3D drawing is consistent with the above workpiece transportation water. If it is not clear, you should promptly report to the programmer or find a fitter to check the 2D drawing to see if the 2D and 3D reference angles are consistent.

5. The program list of CNC Machining Steel files should be standardized, including mold number, name, program name, machining content, tool size, feed rate, especially the safe length of tool clamping, and the remaining amount reserved for each program. The amount and the light knife should be clearly marked. The place where the R surface and the plane should be smoothly connected should be indicated on the program table. The operator should increase 0, 02~0 when processing, whether the connection is smooth, feel whether it is starting by hand, and lower the gong if it is not smooth.

6. It is necessary to understand the content of CNC Machining Steel program table before processing. There must be a 2D or 3D drawing on the program table, and the six-sided data of "X length, Y width, Z height" must be marked,

Where there is a plane, the value of "Z" should be marked, and the operator can easily check whether the data is correct after processing. If there is a tolerance, the tolerance data should be indicated.

7. The processing speed of the machine tool must be strictly controlled by the operator. The F speed and S spindle speed must be adjusted reasonably. When the F speed is fast, the speed of the S spindle must be increased, and the feed speed must be adjusted in different areas. After processing, check the quality before leaving the machine to achieve perfect processing.

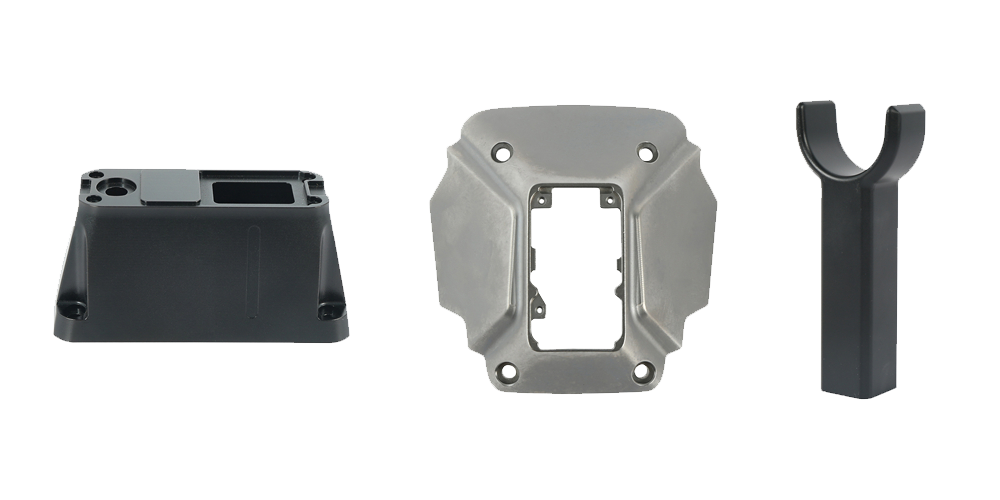

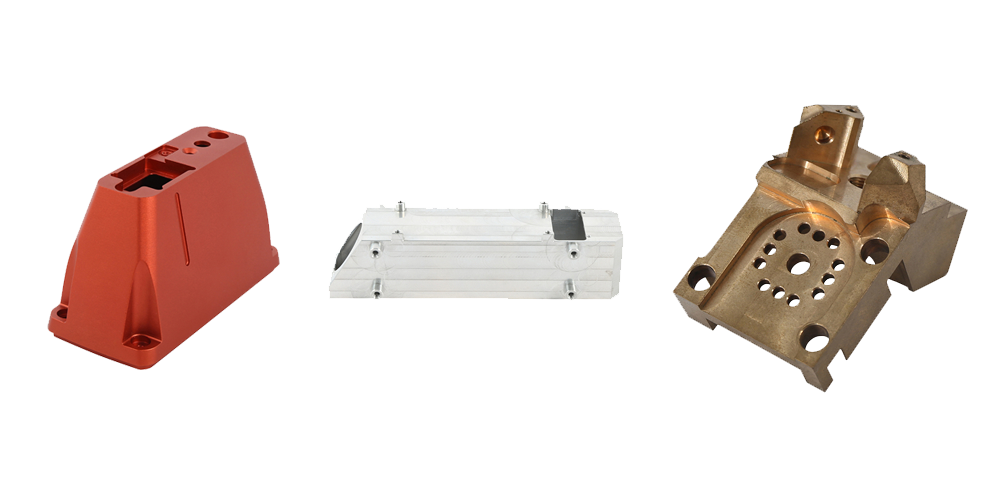

Boyang CNC Machining Steel

China Boyang is a professional CNC Machining Steel supplier, manufacturers. Our mission is to provide customers with high-quality, best-selling products.