China CNC Machining Titanium

CNC Machining Titanium processing has the following advantages:

① The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for the development and modification of new products.

② The processing quality is stable, the processing accuracy is high, and the repeat accuracy is high, which is suitable for the processing requirements of the aircraft.

③ In the case of multi-variety and small batch production, the production efficiency is higher, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the best cutting amount.

④ It can process complex profiles that are difficult to process by conventional methods, and even process parts that are not easy to observe.

The disadvantage of CNC Machining Titanium is that the cost of machine tool equipment is expensive and requires a high level of maintenance personnel.

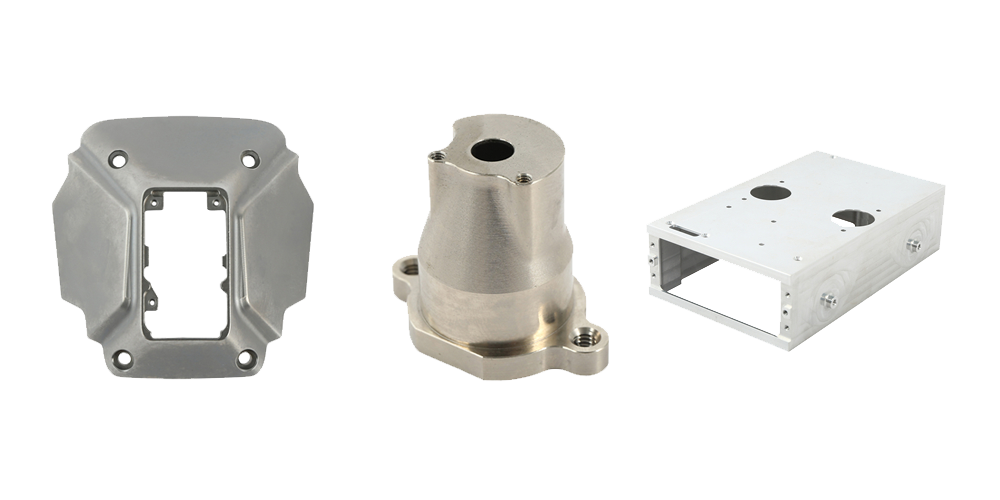

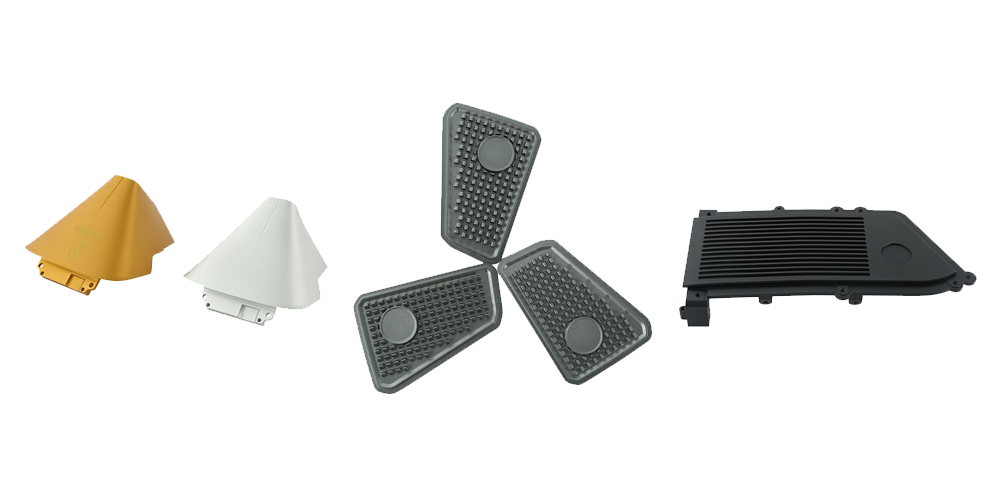

CNC Machining Titanium:

Milling is widely used in titanium alloy structural parts, such as the inner and outer surfaces of parts.

The cutting tool should be selected from materials with high hardness, high bending strength and toughness, good wear resistance, good thermal hardness, good workability, and good heat dissipation, mainly high-speed steel and cemented carbide YG8. The geometric parameters of the tool should be based on the principle of ensuring that the tool has high strength, good rigidity and sharpness. The slenderness ratio should not be too large. There are two types of roughing and finishing. It is best to use down milling during processing.

1. Conventional machining and milling

2. When CNC Machining Titanium is milling, it is necessary to inject enough water-soluble oily cutting fluid to reduce the temperature of the tool and the workpiece. The flow rate of the flow cutting fluid should not be less than 5L/min to extend the service life of the tool.

On the basis of the above-mentioned conventional processing, in order to further improve the efficiency of milling processing, we conducted high-efficiency milling experiments on the powerful milling center machine tool, and obtained ideal cutting parameters, tools and cutting fluids.

3. From the comparison of high-efficiency milling and conventional milling, it can be seen that the efficiency of high-efficiency CNC Machining Titanium is 2 to 4 times higher than that of conventional machining, the quality of surface parts is also greatly improved, the machining cycle is greatly shortened, and the manufacturing cost is correspondingly reduced.

CNC Machining Titanium About CNC Machining

Followed by Dxx radius compensation; during machining, the tool will be on the left side of the workpiece, and then on the right side of the workpiece. Tool radius compensation is related to up and down milling

Followed by Hxx length compensation

The tool is used when feeding from the left side of the workpiece, and the right side is used, and the internal direction is opposite to the arc. As for whether the correction value is negative or not, it depends on the margin you choose. It has nothing to do with length positive compensation and length negative compensation and up and down milling, only related to the length of the tool, generally not used.

CNC Machining Titanium factory quality:

Quality ratio, better strength, toughness and ductility. In addition, CNC Machining Titanium's titanium alloy also has good oxidation resistance and corrosion resistance, and can still maintain good strength at high temperatures. These performance advantages make titanium alloys widely used in aerospace, automotive, chemical and medical equipment and other fields.

CNC Machining Titanium has a tip arc of 0 or 4 for titanium alloy blades. For titanium alloys with a certain degree of hardness and for high temperature alloys, the overall CBN tool is the most ideal tool, and the effect is very good.

Boyang CNC Machining Titanium

China Nextop&GA is a professional CNC Machining Titanium supplier, manufacturers. We focus on producing high-quality products with complete specifications.